17.Oct.2025

Greenhouse Gas and Energy Management

Energy Use and Greenhouse Gas Inventory

1. Energy Consumption

The Company’s primary energy consumption includes low-sulfur fuel oil, diesel, and gasoline for vehicles.

In 2024, total electricity consumption at the plant amounted to 4,002,040 kWh, representing a decrease of 1,017,160 kWh compared to 2023, demonstrating improved energy-saving performance.

To reduce energy consumption, in addition to strengthening source management, promoting energy conservation awareness, and replacing outdated equipment, the Company is also actively developing renewable energy. Through the planning and adoption of renewable energy applications, the Company aims to reduce carbon emissions and decrease reliance on traditional fossil fuels.

Note:For 2024, the lower heating value (LHV) of automotive gasoline is 7,609 kcal/L, the LHV of automotive diesel is 8,642 kcal/L, and the electricity conversion factor is 1 kWh = 0.0036 GJ.

2. Greenhouse Gases

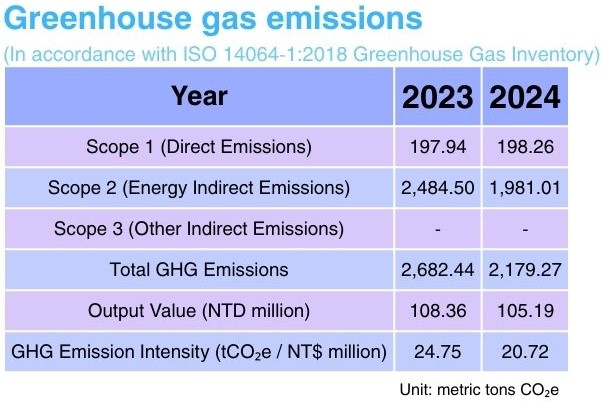

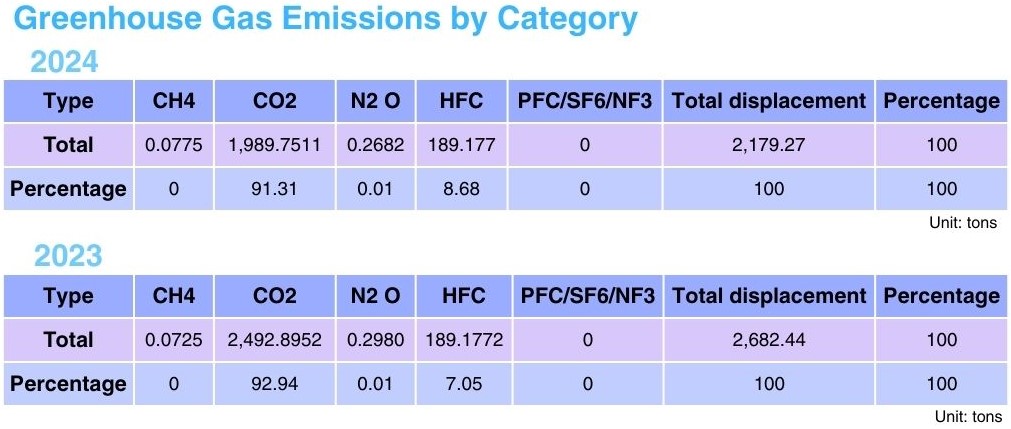

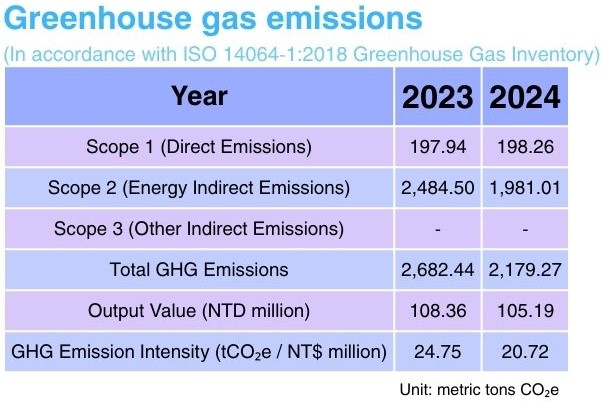

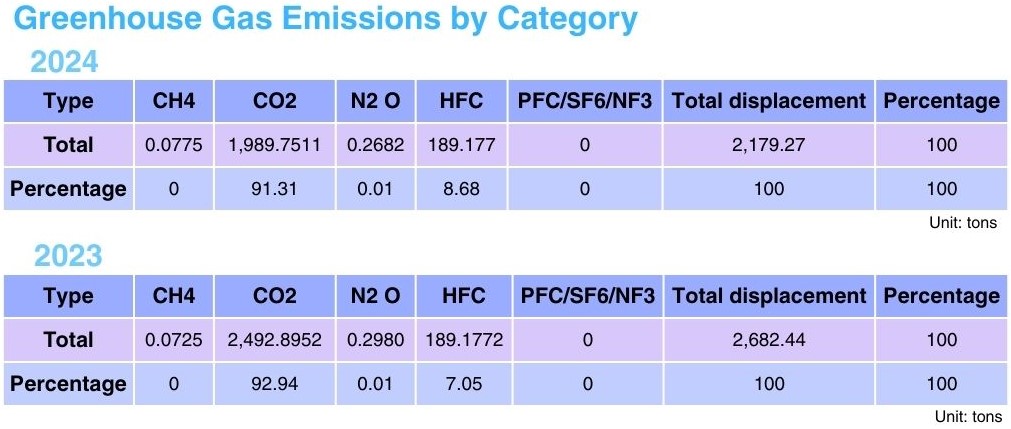

In response to Taiwan’s net-zero emissions policy, East Tender Optoelectronics began conducting self-assessments of greenhouse gas emissions in 2023 in accordance with ISO 14064-1:2018. Verification of the ISO 14064-1:2018 greenhouse gas inventory was completed in the second quarter of 2024.

As shown in the table below, the Company’s primary greenhouse gas emissions are indirect energy-related emissions, with purchased electricity accounting for the largest share. Looking ahead, the Company plans to adopt 2023 as the base year and set an annual carbon reduction target of 1.1%, demonstrating its continued commitment to reducing environmental pollution and mitigating climate impacts.

Note: Category 1 and Category 2 information cover all factory areas.

Carbon Reduction Strategies and Actions

1. Energy Consumption

The Company’s primary energy consumption includes low-sulfur fuel oil, diesel, and gasoline for vehicles.

In 2024, total electricity consumption at the plant amounted to 4,002,040 kWh, representing a decrease of 1,017,160 kWh compared to 2023, demonstrating improved energy-saving performance.

To reduce energy consumption, in addition to strengthening source management, promoting energy conservation awareness, and replacing outdated equipment, the Company is also actively developing renewable energy. Through the planning and adoption of renewable energy applications, the Company aims to reduce carbon emissions and decrease reliance on traditional fossil fuels.

Note:For 2024, the lower heating value (LHV) of automotive gasoline is 7,609 kcal/L, the LHV of automotive diesel is 8,642 kcal/L, and the electricity conversion factor is 1 kWh = 0.0036 GJ.

2. Greenhouse Gases

In response to Taiwan’s net-zero emissions policy, East Tender Optoelectronics began conducting self-assessments of greenhouse gas emissions in 2023 in accordance with ISO 14064-1:2018. Verification of the ISO 14064-1:2018 greenhouse gas inventory was completed in the second quarter of 2024.

As shown in the table below, the Company’s primary greenhouse gas emissions are indirect energy-related emissions, with purchased electricity accounting for the largest share. Looking ahead, the Company plans to adopt 2023 as the base year and set an annual carbon reduction target of 1.1%, demonstrating its continued commitment to reducing environmental pollution and mitigating climate impacts.

Note: Category 1 and Category 2 information cover all factory areas.

Carbon Reduction Strategies and Actions

- Air Conditioning Temperature Control:T emperature controls are implemented for air-conditioning systems in both plant facilities and office areas.

- Energy Efficiency and Time Management: Lighting in unoccupied areas is turned off as appropriate, and lights in office areas are switched off during lunch breaks to save energy.

- Energy-Efficient Lighting: Conventional lighting in plant facilities has been replaced with LED lighting.

- Process Optimization: Energy efficiency is enhanced through process optimization, increased use of renewable energy and circular products, improvements in process and product design, and adoption of low-carbon technologies.

- Digitalization: Electronic systems are established to minimize paper consumption.

- Awareness Promotion: Continuous promotion of energy saving, water conservation, waste sorting and recycling, waste reduction, and encouragement of employees to walk more or use stairs whenever possible.